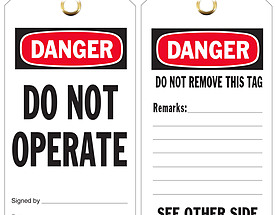

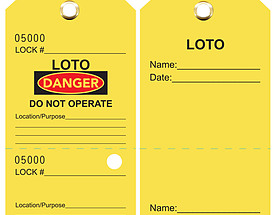

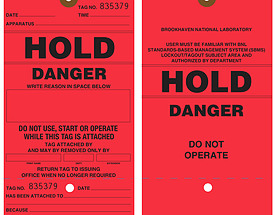

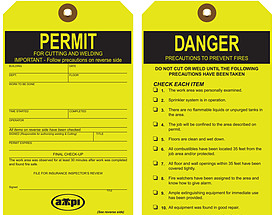

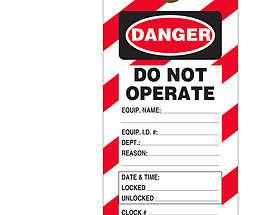

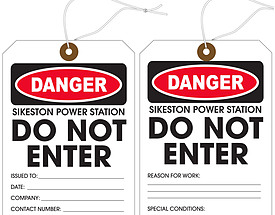

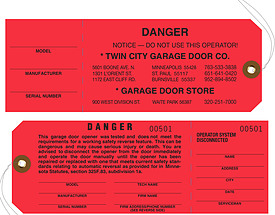

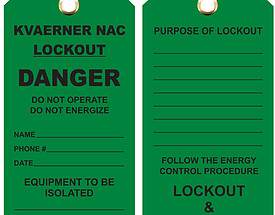

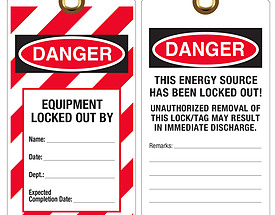

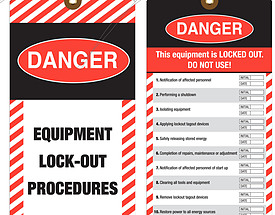

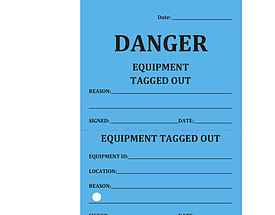

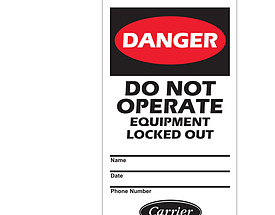

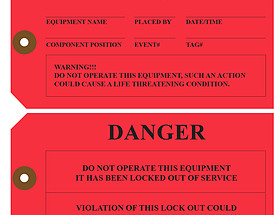

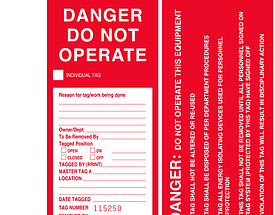

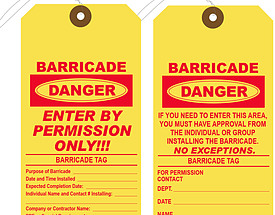

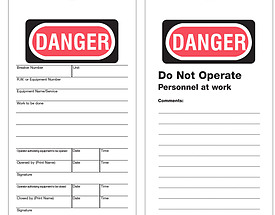

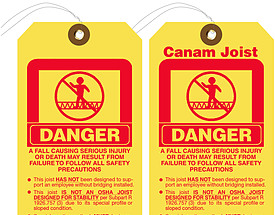

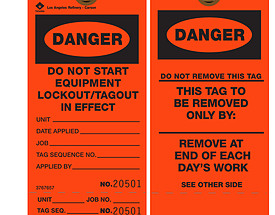

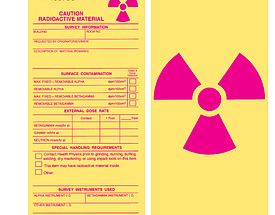

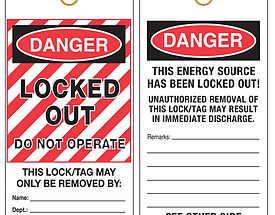

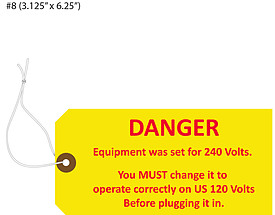

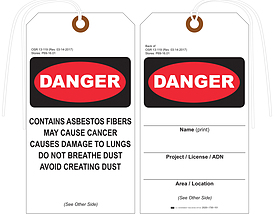

Custom Danger Tags

The purpose of a Danger Tag is to ensure that any non-routine operation or corrective work undertaken on any Plant (equipment), electrical installation, maintenance or servicing of machinery, or equipment with hazardous moving parts or energy, is isolated from the energy source to make it safe, and tagged to indicate the hazards, personnel responsible for the tag and inadvertent re-energizing of the system. St. Louis Tag can customize any danger hang tag to fit your unique needs.

Custom Danger Hang Tags to Match Your Brand

At St. Louis Tag, we take pride in fully customizing hang tags to your requirements and specifications. We can also guide you through the process and make recommendations for your industry needs. View our Danger Hang Tag tag examples below and request a free quote today.

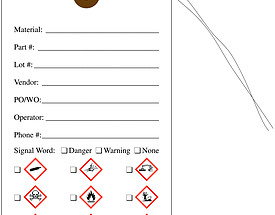

Customization Options to Create Your Ideal Tag

St. Louis Tag offers multiple ways to customize your tags to meet your specific needs. Explore our primary customization options below.

We offer 12 standard sizes that are available as is, with clipped corners or with rounded corners. Fully customized die cut shapes are also available.

We offer numerous material options for tag printing, including high grade printing paper for retail tags, durable Tyvek and vinyl for waterproof hang tags, and carbonless carbon paper for multi-part hang tags.

In addition to the 21 standard colors we offer for our tags, we can create virtually any color by flood coating our white tags. We also offer full-color process printing for creating eye-catching designs with fine details.

Tags are typically punched with either 3/16” or 3/8” holes and can be reinforced with fiber patches and/or metal eyelets for securely attaching tags to items.

We offer several standard string materials, including elastic, mercerized cotton, cotton/poly blend, polished cotton twine and a natural option that is similar to jute. These can either be knotted or looped. For more industrial applications, we offer several different types and gauges of metal wire options.